How to Improve Spraying System of High-efficiency Coating Machine

Writer: admin Time:2021-06-02 11:05 Browse:℃

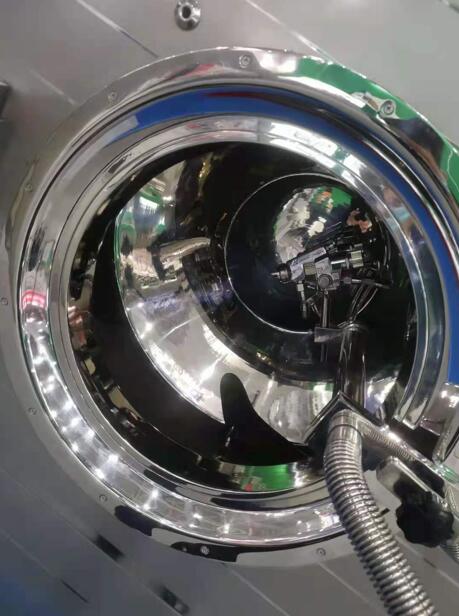

Spraying system is one of the four important parts of high-efficiency coating machine. It is designed to distribute coating liquid to the surface of every tablet as uniformly as possible. A good spraying system can not only beautify tablets, but also improve coating efficiency and reduce wear and tear to tablets. Therefore, an important premise for successful coating production is a good spraying system, together with optimization of working conditions of spraying gun before coating. But how can a good spraying system be useful to improve tablets smoothness, appearance, grade and yield? It can be helpful to improve the system from the following aspects.

1. Optimization of spraying condition

What’s necessary to do before coating is to check leak of the connection pipe for spraying gun, flexibility of gun needle and position of the needle in the spraying nozzle. These factors all influence coating efficiency and quality. If the needle is not at the center of the spraying nozzle, the proportion of coating liquid and high-pressure atomizing gas will change at the nozzle, thus influencing spraying shape and atomizing effect and sometimes even spray pulse. Besides, deviation of gun needle will also cause liquid leaking and tablet cohesion.

2. Position of spraying gun

Usually, the spraying position should be located on the upper 1/3 of the fluid bed. And spray direction can be parallel to the direction of air inlet and vertical to the fluid bed. The distance between spraying gun and fluid bed is variable for different coating liquid, for example, 20-25cmm for organic solution coating while 25-30cm for aqueous coating.

3. Atomizing pressure

Coating effect is also determined by atomization of coating liquid. Large droplets will weaken expansion and agglomeration of tablets and reduce drying speed so that they don’t expand and even cohere to each other, further leading to rougher coat and more bridging, although coat at the edge will not break easily. Besides, when tablet temperature is high, it’s easier for coat to crease. In addition, some droplets contain too much moisture which cannot be fully evaporated before the tablets fall to the lowest point of fluid bed. It might result to wet tablet surface. Once these tablets pile up, cohesion between tablets and between tablets and the machine will occur, especially when tablets are flat or concave. On the other hand, small droplets will expand and distribute easily to reduce coat roughness and bridging. Strong expansion of droplets can also raise drying speed and avoid tablet cohesion. However, at high atomizing pressure or low spraying speed, some small droplets might be dried even before they reach tablet surface. If the temperature of fluid bed is high, phenomenon of “spraying frost” occurs more easily. It’d be better to control atomizing pressure at about 4.5kg/cm2, or within 3.5-5.5kg/cm2. But the actual pressure also depends on coating machine, tablet quality and viscosity of coating liquid.

4. Spraying range

If the spraying range is narrow, less tablets will be covered by the coating liquid and coating uniformity in a unit time will be correspondingly reduced. On the other hand, wider spraying range can make more tablets to be covered. Providing spraying amount and other coating conditions are the same, coating liquid can be distributed to as more tablets as possible in a unit time, thus increasing uniformity of coating and color but reducing consumption of coating liquid.

The spraying range of double-gas-path spraying gun can be adjusted by turning the special screw on the gun, while that of single-gas-path spraying gun adjusted by controlling the distance between spraying gun and fluid bed. Proper spraying ranger can largely heighten coating efficiency and uniformity and reduce tablet cohesion.

Currently, most coating machines are equipped with more than one spraying gun. Wide spraying range might result to overlapping of atomized coating liquid and such liquid massing will lead to tablet cohesion. In this case, while adjusting spraying range, the overlapping of sprayed liquid should also be considered.

Good operation of spraying system is one of the key for successful coating. On our high-efficiency coating machine, we can adjust the system and optimize working conditions carefully before operating for smoother production, higher yield, beautiful tablet appearance and improved grade.